Boring Machine Hydraulic Hose

The Boring Machine Hydraulic Hose is a crucial component used in tunnel boring machines (TBMs). Tunnel boring machines are massive, sophisticated machines designed to excavate tunnels for various purposes, such as transportation, mining, and underground infrastructure.

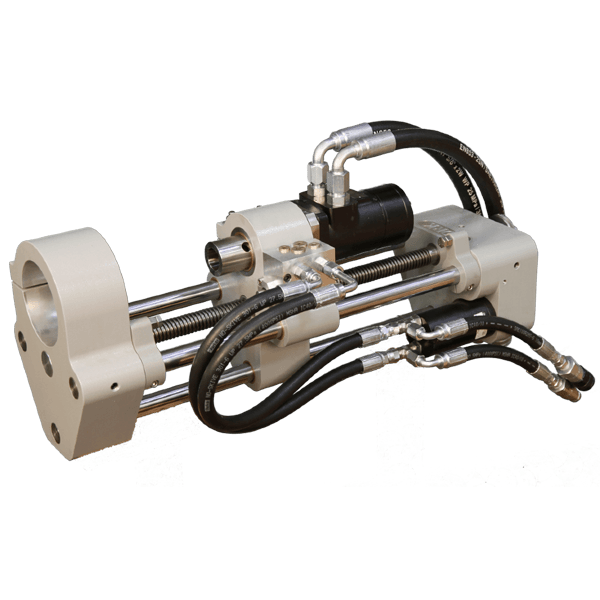

- Purpose: The primary purpose of the hydraulic hose in a boring machine is to transfer hydraulic fluid from one component to another. Hydraulic systems play a vital role in controlling the movements of different parts of the tunnel boring machine, including the cutter head, conveyor system, and support structures.

- Construction: The hydraulic hose is typically made of a flexible rubber or thermoplastic inner tube that is reinforced with multiple layers of high-strength materials, such as braided steel wires or synthetic fibers. The reinforcement provides the hose with strength, flexibility, and resistance to pressure.

- Compatibility: Hydraulic hoses used in boring machines must be compatible with the hydraulic fluid used in the system. Different TBMs may use various types of hydraulic fluids, so it is crucial to select the appropriate hose material to prevent chemical reactions or damage.

- Pressure Rating: Boring machine hydraulic hoses are designed to withstand high-pressure conditions. The pressure rating is specified by the manufacturer and must be chosen according to the hydraulic system’s requirements to ensure safe and efficient operation.

- Size and Length: The size and length of the hydraulic hose vary depending on the specific requirements of the TBM and the distance between various hydraulic components. Hoses may range from a few inches to several feet in length.

- End Fittings: Hydraulic hoses are equipped with specialized end fittings that allow them to be connected securely to other hydraulic components, such as pumps, valves, and cylinders. These fittings are often made of metal and have O-ring seals to prevent leaks.

- Durability and Resistance: Since tunnel boring operations can be challenging and demanding, the hydraulic hose must be durable and resistant to abrasion, impact, and external environmental factors. This ensures a long service life and minimizes the need for frequent replacements.

- Safety Considerations: Safety is of utmost importance when dealing with hydraulic systems. The hydraulic hoses must be properly installed, inspected regularly for wear or damage, and replaced as needed to prevent accidents or system failures.

0

People watching this product now!