Breaker Hose Pipe

A breaker hose pipe, also known as a hydraulic breaker hose or simply a breaker hose, is a critical component used in hydraulic rock breakers. Hydraulic rock breakers are powerful attachments mounted on construction machinery like excavators, skid-steer loaders, or backhoes. They are designed to break or demolish hard materials such as rocks, concrete, and asphalt.

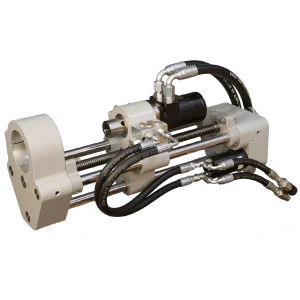

- Purpose: The primary purpose of the breaker hose pipe is to transfer hydraulic fluid from the hydraulic system of the carrier machine (e.g., excavator) to the hydraulic rock breaker. Hydraulic fluid under pressure is used to power the breaker’s piston, which delivers impact energy to the chisel or tool at the breaker’s tip, breaking through tough materials.

- Construction: Breaker hoses are typically made of a flexible and robust rubber or thermoplastic inner tube reinforced with multiple layers of high-tensile steel wire braids. The reinforcement provides the hose with strength and flexibility, allowing it to handle high-pressure hydraulic fluid without bursting.

- Pressure Rating: Breaker hose pipes are engineered to withstand extremely high hydraulic pressures. The pressure rating is specified by the manufacturer and must be suitable for the hydraulic system’s requirements to ensure safe and efficient operation of the rock breaker.

- Size and Length: The size and length of the breaker hose pipe depend on the specific requirements of the hydraulic rock breaker and the distance between the hydraulic system and the breaker attachment on the carrier machine. Hose lengths can vary from a few feet to several meters.

- End Fittings: Breaker hose pipes are equipped with specialized end fittings at both ends, allowing them to be securely connected to the hydraulic system of the carrier machine and the hydraulic rock breaker. These end fittings typically have threaded connections or quick couplers for easy and safe attachment.

- Durability and Resistance: Breaker hose pipes are subjected to harsh conditions during rock breaking operations, including exposure to abrasion, impacts, and debris. As a result, they are designed to be highly durable and resistant to wear and tear, ensuring a longer service life.

- Safety Considerations: Safety is paramount when dealing with hydraulic systems, especially in rock breaking applications. The breaker hose pipe must be installed correctly and inspected regularly for signs of wear, damage, or leaks to prevent accidents and equipment failures.

0

People watching this product now!