Hydraulic Hose

A hydraulic hose is a flexible conduit used to transmit hydraulic fluid between various hydraulic components in a hydraulic system. It is a crucial part of hydraulic machinery and equipment and plays a vital role in the efficient and safe operation of various industries, including construction, agriculture, manufacturing, mining, and transportation.

Description:

- Construction: Hydraulic hoses are typically constructed with a flexible inner tube made of synthetic rubber or thermoplastic material. The inner tube is reinforced with multiple layers of high-strength materials, such as braided steel wire or spiral-wound steel wire, to handle the high-pressure hydraulic fluid without bursting or leaking.

- Pressure Rating: Hydraulic hoses are designed to withstand high hydraulic pressures. The pressure rating is specified by the manufacturer and must be chosen based on the specific hydraulic system’s requirements to ensure safe and reliable operation.

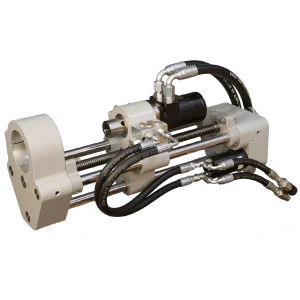

- Size and Length: Hydraulic hoses come in various sizes and lengths, depending on the hydraulic system’s design and the distance between hydraulic components. Hose lengths can range from a few inches to several feet or even longer.

- End Fittings: Hydraulic hoses are equipped with specialized end fittings on both ends, allowing them to be securely connected to hydraulic pumps, valves, cylinders, and other hydraulic components. The end fittings may have threaded connections or quick couplers for easy installation and maintenance.

- Fluid Compatibility: Hydraulic hoses must be compatible with the hydraulic fluid used in the system. Different hydraulic systems may use various types of hydraulic fluids, such as mineral oil, synthetic fluids, or water-based fluids. Using the wrong type of hose can lead to chemical reactions, degradation, and system failures.

- Temperature Resistance: Hydraulic hoses should be designed to withstand a wide range of temperatures, as hydraulic systems can operate in both hot and cold environments. The hose materials must remain flexible and functional across the expected temperature range.

- Abrasion and Wear Resistance: Hydraulic hoses are often exposed to harsh environments, including abrasive materials and rough surfaces. They must be designed to resist abrasion and wear to ensure a longer service life.

- Safety Considerations: Proper installation, regular inspection, and maintenance of hydraulic hoses are essential for the safe operation of hydraulic machinery. Damaged or worn-out hoses should be promptly replaced to prevent accidents and ensure the integrity of the hydraulic system.

0

People watching this product now!