Forklift Hydraulic Hose

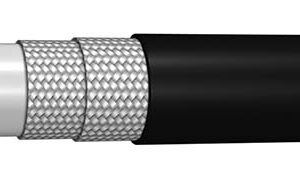

A forklift hydraulic hose is a critical component of a forklift’s hydraulic system, responsible for transmitting hydraulic fluid from one part of the system to another. Hydraulic hoses are flexible tubes made of rubber or thermoplastic materials reinforced with multiple layers of braided or spiraled high-strength synthetic fibers or steel wire.

Here is a detailed description of a forklift hydraulic hose:

- Material: The hose is typically made of high-quality rubber or thermoplastic materials to ensure flexibility, durability, and resistance to hydraulic fluid, abrasion, and external environmental factors.

- Reinforcement: The inner tube of the hydraulic hose is reinforced with multiple layers of braided or spiraled high-strength synthetic fibers or steel wire. This reinforcement provides the hose with the necessary strength to handle high-pressure hydraulic fluid.

- Pressure Rating: Forklift hydraulic hoses are designed to handle specific pressure ratings, usually measured in pounds per square inch (psi) or bar. The pressure rating determines the maximum pressure the hose can withstand without rupturing or leaking.

- Temperature Range: The hydraulic hose should be capable of operating within a specific temperature range to ensure optimal performance and prevent damage. The temperature range varies depending on the materials used in the construction of the hose.

- Fittings: Forklift hydraulic hoses come with fittings on each end. These fittings are typically made of steel and are crimped or threaded onto the hose ends. They allow for a secure connection to other hydraulic components such as pumps, cylinders, valves, and reservoirs.

- Size and Length: Hydraulic hoses come in various sizes and lengths to accommodate different forklift models and hydraulic system configurations. The length of the hose determines how far hydraulic fluid can travel within the system.

- Compatibility: It is crucial to ensure that the hydraulic hose is compatible with the specific hydraulic fluid used in the forklift’s system. Using the wrong type of hose or hydraulic fluid can lead to damage and reduced performance.

- Safety: Proper maintenance and inspection of hydraulic hoses are essential to prevent accidents, leaks, and potential system failures. Regular checks for wear, damage, or signs of deterioration are vital to ensure the safe operation of the forklift.

- Identification: Hydraulic hoses often have printed information on the outer surface, indicating important details such as the manufacturer, part number, pressure rating, temperature range, and manufacturing date.

0

People watching this product now!